All Manufacturing ERP solutions are centralized, all departments of the organisation can access and view the production data in real time. For instance, the engineering team can monitor the progress of the production floor and update the purchasing to finance departments about the requirement of additional raw materials.

Most Manufacturing setups have to focus on getting these right with a robust ERP system in place viz.

Factory Productivity & Production

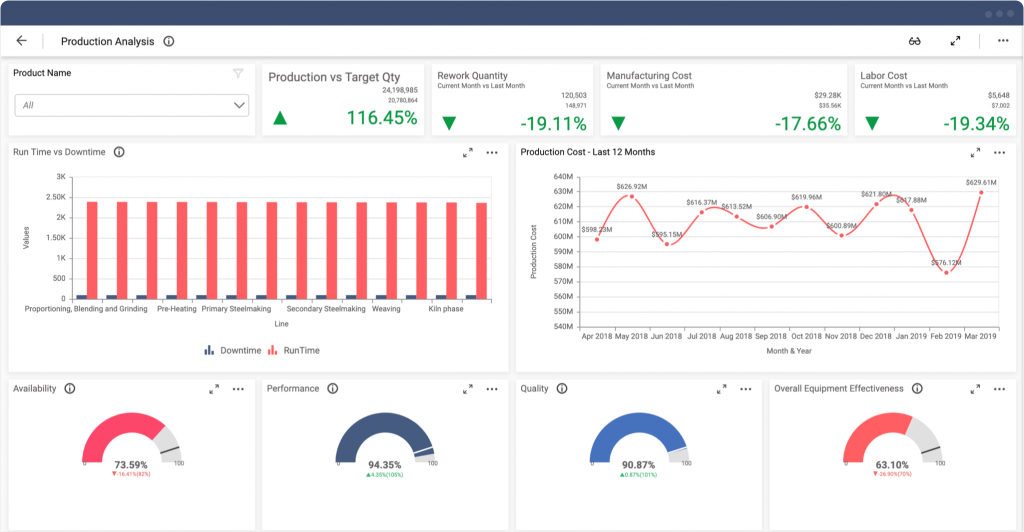

Credits: BoldBI

Before the dawn of dotcom era, manufacturing performance of factory workers was dependent on the floor manager or the factory managers feedback. There was no definitive way of attributing the success of production to the factory labor.

Setting concrete Daily, Weekly, Monthly targets along with mapping the lanes, devices in the factory setup will help understand the executives to understand the ins and outs of daily performance

Quality Control

Managing the following realtime viz.

- SOP Adherence of Product Quality

- Documenting Quality Scores

- Understanding Product returns

helps the factory managers understand the steps to be taken to ensure Quality Control meets and exceeds the threshold.

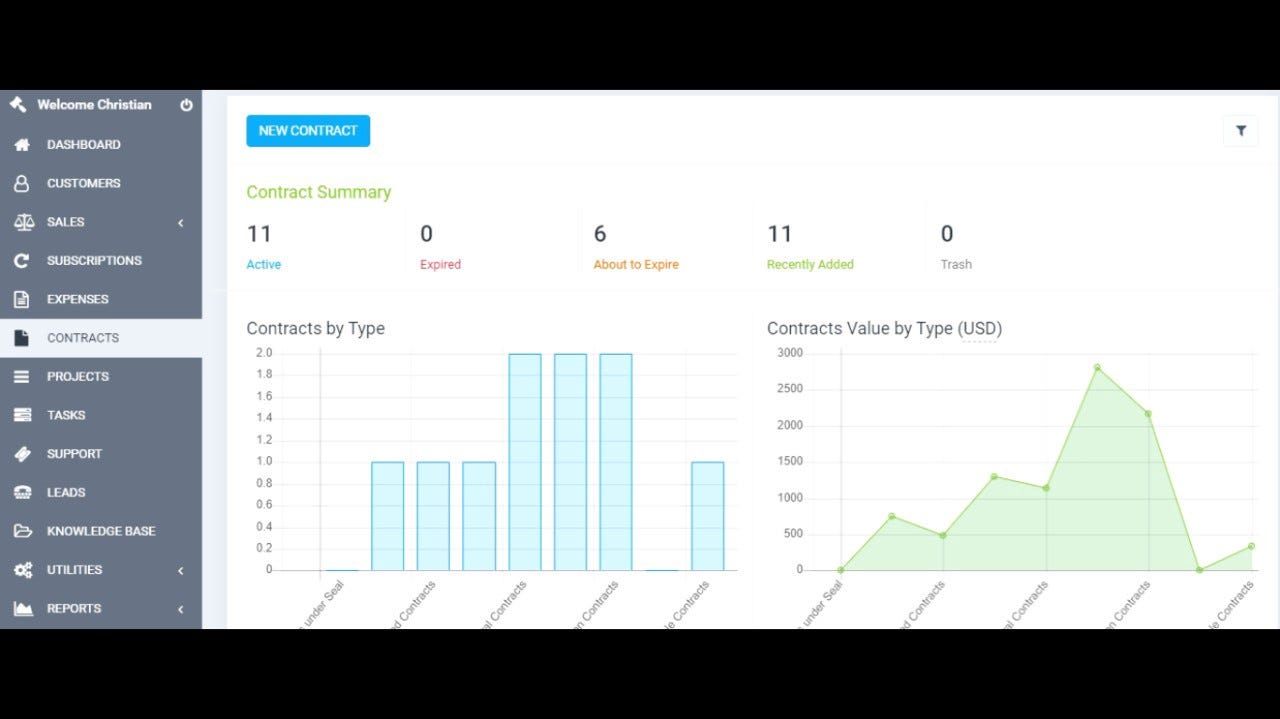

Contracts and Operations with third Parties

Real-time visibility of,

- Production status

- Inventory

- Supply requisitions will give the C Suite a holistic view to manage their operations with business partners

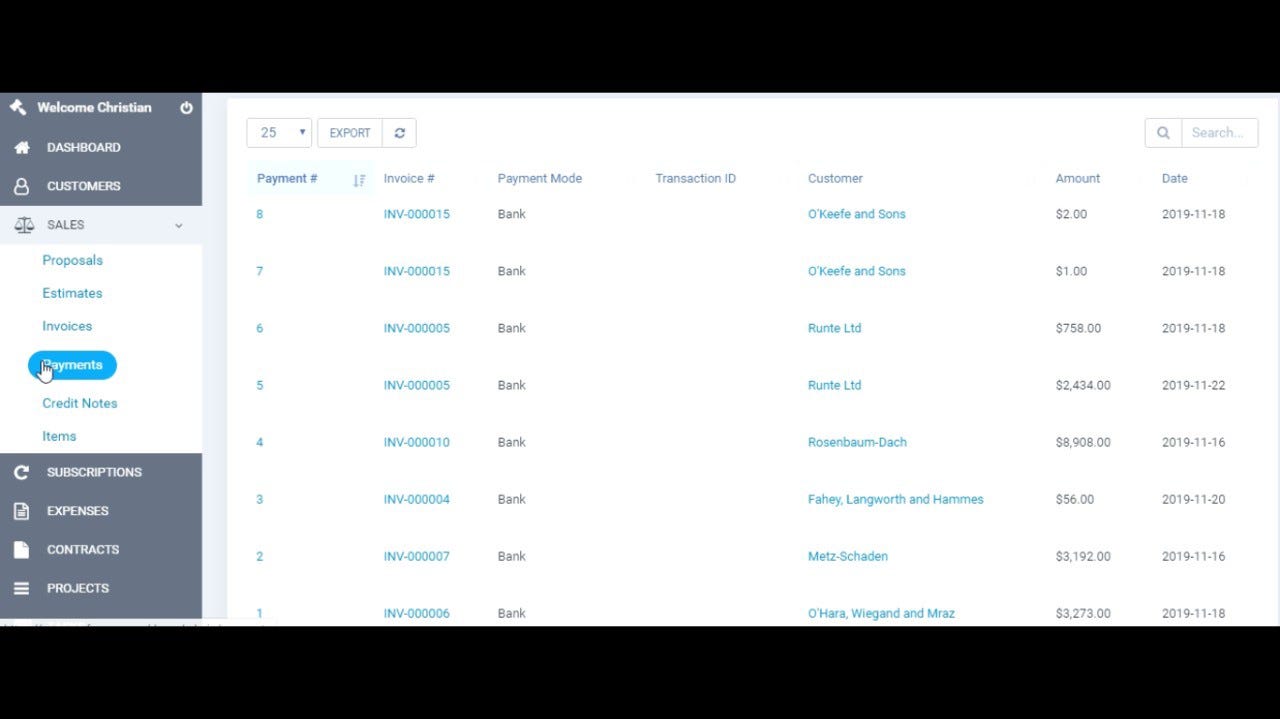

Organization Wide Flow of Data, Communication

ERP Facilitates Seamless coordination and execution of all related processes and procedures, thereby, streamlining the entire manufacturing process.

Real time data visibility and Communication with Logistics, Purchase, Payments, Planning functions help the entire organization stay on the same page and drive better outcomes

About Us: Infusai is an end to end Microsoft business and platform service provider. We design, build, implement and support enterprise CRM, ERP solutions & custom applications.